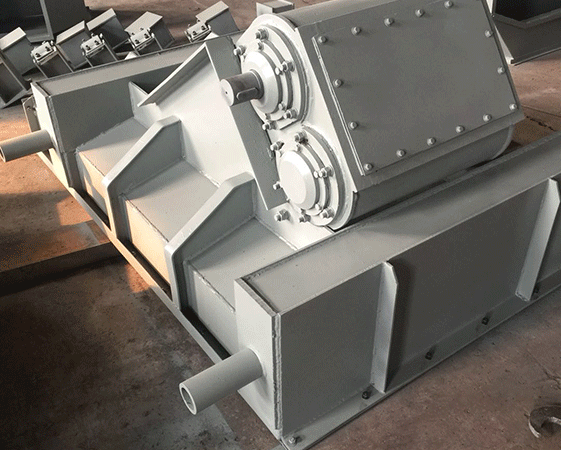

The use of simple structure, fatigue resistance, long life, can withstand 18 hours of daily operation fatigue and uninterrupted operation. Can achieve safe operation of 30,000 hours of work without major repairs. 500-2100 hours only need to fill the four bearings with lithium base grease once. Low operating cost, low maintenance cost, convenient and time-saving. The main technical structure is a two-shaft integrated box type vibration exciter, four sets of rolling bearings bearing two vibration crankshafts, with two motors with the same power and speed universal flexible connection. The two vibration shafts running in the opposite direction are self-synchronized and linearly forced to vibrate, so that the material jumps forward in the bottom plate of the feeder tank according to the 35° throwing Angle, 960 times per minute, and the amplitude is 6-8mm each time.

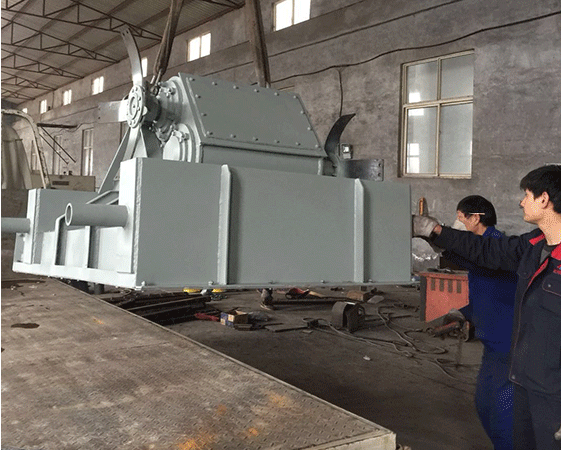

GZM series feeder is reflected in the shortcomings of several feeders in the market, our factory jointly developed with the science and technology department of coal preparation Branch, to overcome the vibration motor fatigue resistance and long-term large feed continuous operation, but also on the basis of the original technical characteristics of the GZY type vibration box, cancel a pair of gears, driven by one motor to two self-synchronization. But does not increase the power of the motor. After the cancellation of the gear, it overcomes the shortcomings of loud noise of the feeder, gear teeth, and the need for wet lubrication resulting in oil leakage and environmental pollution. Overcome the GZY exciter horizontally installed on the feeder tank body, resulting in up and down vibration frequency track long, so that the material up and down jump more, can not throw a walk the forced characteristics.

GZM installs the vibration box 35° on the tank body, so that the material jumps forward and upward according to the 35° trajectory. The full use of vibration power, due to this improvement to improve the transmission capacity, reduce noise and resonance to the foundation and the equipment itself caused damage. Make the whole machine run more reliable, according to the actual use of each coal mine can reach 32,000 hours without overhaul.

1, the main technical structure for the dual shaft integrated box exciter, four sets of rolling bearings bearing two vibration crankshaft, with two sets of power speed motor universal flexible connection. The two vibration shafts running in the opposite direction are self-synchronized and linearly forced to vibrate, so that the material jumps forward in the bottom plate of the feeder tank according to the 35° throwing Angle, 960 times per minute, and the amplitude is 6-8mm each time. In order to ensure that the output can be expanded later, 160 box exciter is used with the main engine.

2. The fastening bolts of the exciter and the tank body must use interference riveting bolts.

3, box type vibration exciter crankshaft is thickened crankshaft, center surface thickened, the whole 45# steel casting processing.

4, the motor base and spring support are disconnected design, and can be adjusted for tilt Angle.

The above seemingly simple adjustment, but condensed a lot of efforts of our technical personnel.

Sales hotline+86 13963743295

Company emailchangrunzhizao@163.com

Company addressJining City, Shandong Province, South Zhang Industrial Park, run intelligent manufacturing South Zhang Industrial Park, run intelligent manufacturing